Next: Conducting PRBS Test on Up: PRBS Modelling Previous: PRBS Modelling

SBHS is an example of a heater. Suppose you are working in a full scale plant. Current control system designed to control

one of the heaters of the plant is lousy and your supervisor asks you to design a new controller from scratch. The first step

you need to do is identification of the heater transfer function. The catch is, the plant is currently

operational. You can't shut the plant down to identify the heater transfer function. You have to do it while the heater is

operating in the plant. You might think of giving the heater a positive step and measuring the response in the controlled

temperature. This will increase the temperature of the component being heated for the period of time step is applied. However,

if the process is sensitive to temperature of the component (distillation, for example), it will go off the desired course and

the output of the whole plant will be affected and will be undesirable.

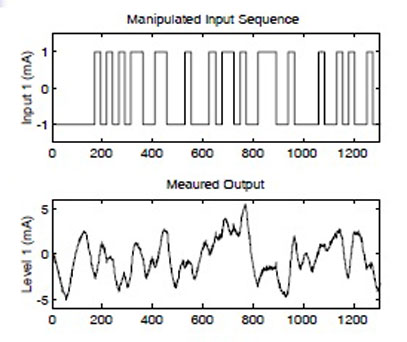

There is an alternate approach which is widely used in industry. The input given to the heater for identification is not step, but a pseudo-random binary sequence (PRBS). The concept behind PRBS is that the input is perturbed in such a way that the time average of the input is the value at which it is being operated currently. Thus, some positive and some negative steps can be given. This results in some positive and some negative changes in the temperature which leads to the time average of the performance of the plant remaining the same. Thus, PRBS testing can be done in a working plant without affecting the plant performance unlike step testing. A typical PRBS and corresponding plant output is shown in figure 7.2

|

rokade 2017-04-23